Application Of Lyocell Fiber

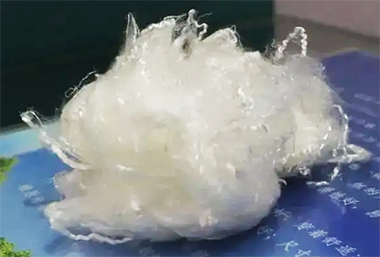

Another feature of Lyocell fiber that can not be ignored is the fibrillation phenomenon, which is the fiber in the wet state due to fiber swelling and mechanical external force, so that the original single fiber in the axial split, split into a smaller fibrillar. Fibrillation is a common feature of all cellulose fibers, but Lyocell is more serious.

The fibrillation of fiber is easy to cause fuzz and pilling, which affects the appearance and dyeing. However, this property can also be fully exploited to become an advantage, in the fiber manufacturing and processing process to regulate the fibrillation to prepare peach wool fabrics, filter materials and special paper.

The application of Lyocell fiber should give full play to its own characteristics.

High hygroscopic property is its essential feature, it gives the fabric good wear performance, therefore, it is very suitable for the manufacture of clothing, especially high-end clothing, because of its high modulus, so that the fabric has excellent conformal property.

In addition, the use of its high hygroscopicity and high strength can be made of denim series of clothing. In the past, denim was made of cotton, but cotton was low in strength and did not wear well. The high strength of Lyocell fiber is the ideal material for making denim.

Lyocell fibers are biodegradable and, therefore, ideal for the manufacture of disposable sanitary materials. At present, many viscose fibers have been used in nonwoven fabrics, but because of the low strength of viscose fibers, especially the low wet strength, the performance of the final product is low. Using the high strength of Lyocell fiber, ultra-short Lyocell fiber made of collapsible nonwovens has appeared on the market.

Compared with viscose fiber, due to the high crystallinity of Lyocell fiber, the initial temperature of thermal decomposition is higher than that of viscose fiber, the thermal weight loss is less, the dynamic modulus changes little, the fiber strength reduction is less, the elongation at break can also meet the processing and use requirements, has good heat resistance, and the thermal shrinkage rate is low, and the combustion condition is basically the same as that of viscose fiber. When Lyocell fiber is kept at 190℃ for 30min, the breaking strength and elongation at break of the fiber are 88.4% and 88.6% of the original value, respectively, showing good heat resistance.

Related News

Submitted successfully

We will contact you as soon as possible