What are viscose fiber, Modal fiber and Lyocell fiber respectively

Viscose fiber, modal fiber, Lyocell fiber is a kind of man-made fiber. Raw materials are also from plants, trees, cotton, bamboo and other natural cellulose, natural, renewable, especially Modal and Lyocell, the preparation process is environmentally friendly, belong to the green fiber.

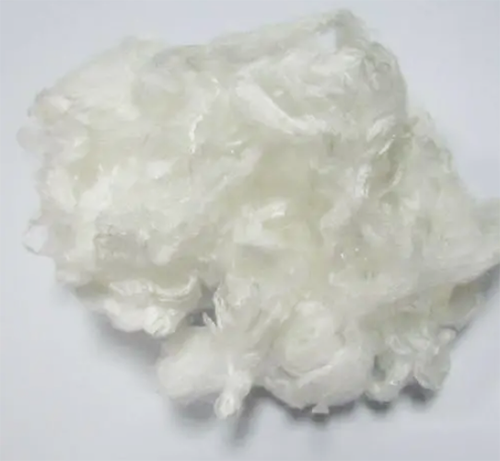

Viscose Fiber

In 1892, viscose fibers were invented by Charles Cross and Edward Bevan. They treated cellulose with caustic soda and carbon bisulfite to produce a thick, honey-like viscous liquid, which they named viscose! In 1899, Charles Topham bought the rights to make fibers from viscose, but also struggled to make them strong enough. Inspired by spinning bicycle wheels, the "Topham Box" was developed, which can spin at 3,000 RPM and throw out perfect viscose fibers. Within months, he was producing 12,000 pounds a day and soon licensing it to manufacturers around the world

Process: Cellulose reacts with carbon sulfide to produce cellulose xanthic acid, and then xanthic acid is turned into viscose with lye. After dehydration, bleaching, pickling, dyeing and other processes, fiber is made.

Viscose fiber fiber has soft, moisture absorption, air permeability and other characteristics, while its strength is low, easy to break.

Modal Fiber

In 1951, Japan invented it, and in 1964, Austria's Lenzing company officially developed Modal fiber. At present, the domestic supply of Modal fiber is mainly three companies: Bola, Lanjing, Tangshan Sanyou

Process method: The wood pulp fiber is specially treated and made into fiber by chemical method.

Modal fiber has high strength, softness, luster and other characteristics, its moisture absorption is higher than cotton fiber, but lower than viscose fiber.

Lyocell Fiber

In 1972, an American company developed a process to eliminate carbon disulfide by directly dissolving cellulose in the less toxic and more environmentally friendly N-methylmorpholine n-oxide (NMMO), the so-called Lyocell process. The company went bankrupt before it could bring the product to market, but the process was adopted in the 1980s by Courtaulds Fibres, which the company called Tencel (US brand name).

Process method: The wood pulp fiber is dissolved in an environmentally friendly solvent NMMO (N-methylmorpholine oxide) to make the fiber.

Lyocell fiber has the characteristics of high strength, softness, gloss, good moisture absorption, good air permeability, etc. It is softer than cotton fiber and more durable than viscose fiber.

In general, these three man-made fibers have soft, shiny and other characteristics, but viscose fiber fiber strength is lower, easy to break, while Modal fiber and Lyocell fiber have better strength and durability.