Production Process Of Lyocell Fiber

Production Process Of Lyocell Fibers

1.Chemical delignification

The raw material of Lyocell fiber is usually cellulose material such as natural wood pulp, which first needs to be treated with chemical delignification. Chemical delignification refers to the removal of non-cellulose components such as lignin from wood by chemical methods, mainly using alkaline substances such as zinc oxide and sodium oxide for delignification. The purpose of this step is to remove non-cellulosic impurities from the raw material and improve the efficiency and fiber quality of the subsequent cellulose regeneration process.

2.Cellulose regeneration

After chemical delignification treatment, the cellulose raw material can carry out the process of cellulose regeneration. Cellulose regeneration refers to the cellulose molecules in the treated raw material are dissolved again in a solvent to form a cellulose solution. Commonly used solvents are mainly ammonia and N-methylmoramine, among which ammonia is the earliest application of solvents. After adding cellulose raw materials, the cellulose molecules are gradually dissolved by adjusting the temperature, pressure and other parameters to form cellulose solution.

3.Fiber forming

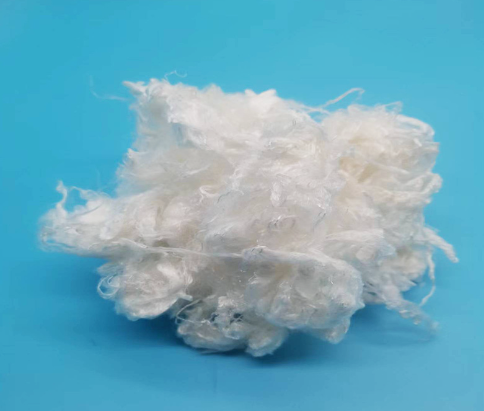

After the cellulose regeneration solution of Lyocell fiber is filtered and dehydrated, it can be processed for fiber forming. There are two main methods of fiber forming: wet spinning and dry spinning. Wet spinning is a process in which cellulose solution is ejected through micro-pores to form fibers under the action of air flow and tensile force. Dry spinning is by dewatering cellulose solution at a certain temperature to form dry solid fiber, and then by stretching, heat setting and other processing to form fiber. Finally, Lyocell fiber products can be made after post-treatment and other steps.

The production process of Lyocell fiber is relatively complicated, and the process control of cellulose regeneration is relatively key. In general, the production process of Lyocell fiber is divided into three steps: chemical delignification, cellulose regeneration and fiber forming. In the process, it should be noted that the selection and treatment of raw materials, the preparation of solutions and the control of the processing process need to be paid great attention to in order to produce high-quality Lyocell fiber products.