The difference and application of regenerated cellulose fiber and Lenzing tencel

I. Overview of regenerated cellulose fibers and Lenzing tencel

Regenerated cellulose fiber and Lenzing silk are emerging fiber materials in recent years, which have attracted much attention for their environmental protection and high-tech characteristics.

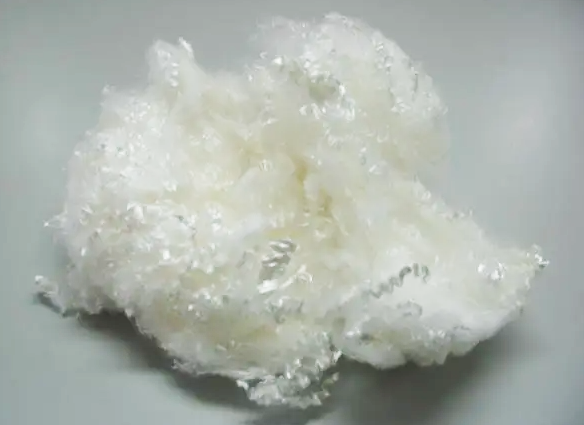

Regenerated cellulose fiber is the natural fiber (such as wood, cotton, linen, etc.) or waste textiles after chemical treatment of artificial fiber, with biodegradability, environmental protection and other advantages, can be used in textile, health and other fields.

Lenzing tencel is a synthetic fiber cloned from sericin gene by means of biotechnology. It has high strength, elasticity, softness and skin affinity. It is a kind of high-grade fiber material, which is widely used in clothing, home textile and other fields.

2. Raw materials

The raw materials of recycled cellulose fibers are mainly from natural fibers and waste textiles, such as wood, cotton, linen, silk, etc., which are usually processed by chemical methods and then spun into fibers.

The raw material of Lenzing tencel is the sericin gene in the silk gene, which is artificially synthesized by means of biotechnology and does not involve any animals in the production process, so it has high environmental protection.

3. Production process

The production process of regenerated cellulose fiber includes pretreatment, spinning, processing and so on, among which chemical pretreatment is the most critical step to manufacture regenerated cellulose fiber.

The production process of Lenzing tencel is complex, including gene cloning, fermentation, worsted and other steps. It is necessary to clone the sericin gene first, then obtain the sericin protein solution by means of biotechnology, and then obtain the fiber through worsted and other steps.

4. Performance

Regenerated cellulose fiber has good air permeability and skin affinity, good softness, but poor strength and durability, easy to wear, pilling.

Lenzing tencel has good strength, elasticity and softness, is also easy to maintain, comfortable to wear, but the price is higher.

5. Application

Recycled cellulose fibers can be used in the production of sanitary products, underwear, sportswear and more. In addition, disposable masks, face towels, wipes and other disinfection supplies can be made.

Lenzing Tensilk has a wide range of applications, especially in high-end clothing, home textiles and other fields, can make all kinds of shirts, skirts, bedding, curtains and so on.

Although both regenerated cellulose fiber and Lenzing tencel are man-made fibers, their raw materials, manufacturing processes, properties and applications are quite different. Understanding these characteristics helps us to have a deeper understanding of the application and advantages and disadvantages of these two fiber materials.